Full-process production from the source factory

with customization support.

A professional manufacturer of cosmetic plastic containers with extensive experience.

⇒Best quality assurance system, most favorable price, fastest delivery time.

⇒Provide over 100 different product specifications for selection.

⇒Professional product development team and support pre-phase new product development services.

⇒Samples are provided free of charge. Proofing can be completed within 7 days, delivery within 20 days,

and for new product development, sample confirmation (including mold making) can be done within 60 days.

Over 15 years of experience in the cosmetic packaging industry,along with an advanced management system, an experienced management and technical team

15 mold-making, 60 injection molding, 15 blow molding machines, 2 spraying/electroplating lines, 18 printing & hot stamping machines, 10 assembly lines, plus an advanced material feeding system and automated assembly equipment.

Taking full charge throughout the process—from initial business negotiations, sampling and confirmation to subsequent production, shipment and after-sales service—providing you with a one-stop full-process service

Available Product Materials

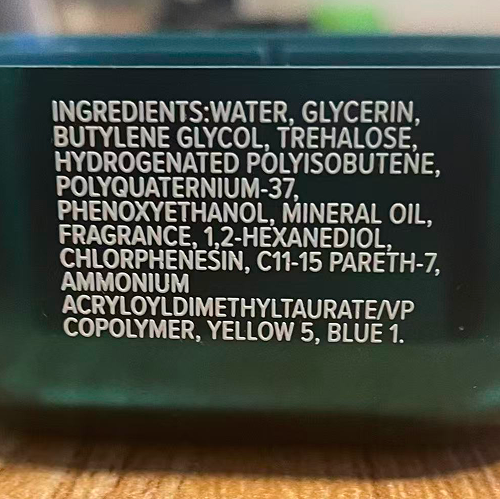

All products are made from food-grade & recyclable PMMA, PETG, PP, AS, and ABS materials (compliant with FDA/REACH standards), with multiple types, sizes, and decorative finishes (spraying, electroplating, etc.) available for customization.

Our Products

We specialize in three core product lines: Skincare Packaging, Color Cosmetics Packaging, and Daily Chemical Packaging. Our product range includes:

- PMMA (Polymethyl Methacrylate) material: Cream jars, lotion bottles, airless bottles

- PETG (Polyethylene Terephthalate Glycol) material: Cream jars

- PP (Polypropylene) material: Cream jars, lotion bottles, airless bottles

- PET (Polyethylene Terephthalate) material: Cream jars, lotion bottles

- Deodorant bottles

- Color cosmetics: Powder compacts

- AS (Acrylonitrile Styrene) material: Airless bottles

3g-280g PETG Cream Jar with Screw Cap

▶ Color: Pantone-matched or custom color ▶ Surface Processes: Spraying, electroplating, hot stamping, printing (silk screen/offset printing), etc.

- Material:Cap:ABS;Jar:PETG;Disk : PE;

- Capacity:3g;5g;10g;15g20g;

- 3g:Diameter:30.5mm/Height:19.5mm;

- 5g:Diameter:36mm/Height:25mm;

- 10g:Diameter:39.5mm/Height:29mm;

- 15g:Diameter:41.5mm/Height:31mm;

- 20g:Diameter:41.5mm/Height:37mm;

30g-100g PETG Cream Jar with Screw Cap

▶ Color: Pantone-matched or custom color ▶ Surface Processes: Spraying, electroplating, hot stamping, printing (silk screen/offset printing), etc.

- Material:Cap:ABS;Jar:PETG;Disk : PE;

- Capacity:30g;50g;80g-1;80g-2;100g-1;

- 30g:Diameter:49.5mm/Height:39.5mm;

- 50g:Diameter:55.5mm/Height:43.5mm;

- 80g-1:Diameter:60mm/Height:58mm;

- 80g-2:Diameter:68mm/Height:50.5mm;

- 100g-1:Diameter:68mm/Height:65mm;

100g-280g PETG Cream Jar with Screw Cap

▶ Color: Pantone-matched or custom color ▶ Surface Processes: Spraying, electroplating, hot stamping, printing (silk screen/offset printing), etc.

- Material:Cap:ABS;Jar:PETG;Disk : PE;

- Capacity:100g-120g;150g;200g;250g;280g;

- 100g:Diameter:83.5mm/Height:36.5mm;

- 120g:Diameter:83.5mm/Height:41.5mm;

- 150g:Diameter:83.5mm/Height:51mm;

- 200g:Diameter:83.5mm/Height:63.5mm;

- 250g:Diameter:83.5mm/Height:74mm;

- 280g:Diameter:92mm/Height:71.5mm;

PMMA Skincare Bottles

▶ Color: Pantone-matched or custom color ▶ Surface Processes: Spraying, electroplating, hot stamping, printing (silk screen/offset printing), etc.

- Material:Bottle body: PMMA | Cap: ABS | Inner liner: PP | Pump head: PP

- Capacity:30g,50g,30ML,50ML100ML,

- 30g:Diameter:70mm/Height:62mm;

- 50g:Diameter:80mm/Height:75mm;

- 30ML:Diameter:45mm/Height:154.5mm;

- 50ML:Diameter:45mm/Height:.184.5mm;

- 100ML:Diameter:55mm/Height:201mm;

100g-150g PP Cream Jar with Flip Cap

▶ Color: Pantone-matched or custom color ▶ Surface Processes: Spraying, electroplating, hot stamping, printing (silk screen/offset printing), etc.

- Material:Cap:PP; Jar :PP; Liner:PP; Disk:PP; Scoop : PP;

- Capacity :100g; 150g;

- 100g; Diameter : 82mm; Height : 59mm;

- 150g: Diameter : 82mm; Height : 77mm;

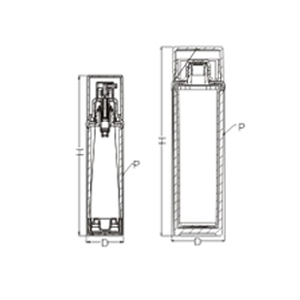

High-Quality Airless Bottle / Lotion Bottle

▶ Color: Pantone-matched or custom color ▶ Surface Processes: Spraying, electroplating, hot stamping, printing (silk screen/offset printing), etc.

- Material : Bottle body: AS/MS ;

- Capacity :50ml, 100ml, 120ml.

- 50ml: Diameter : 32.5mm; Height : 74.5mm;

- 100ml:Diameter : 46.5mm; Height : 181.5mm;

- 120ml:Diameter : 50mm; Height : 177mm;

Airless Cream Jar with Pump

▶ Color: Pantone-matched or custom color ▶ Surface Processes: Spraying, electroplating, hot stamping, printing (silk screen/offset printing), etc.

- Material: Bottle body: PMMA

- Capacity :30g , 50g , 100g.

- 30gl: Diameter : 63 mm; Height : 72 mm;

- 50g : Diameter : 63 mm; Height : 83 mm;

- 100g : Diameter : 63 mm; Height : 110 mm;

PP/AS Deodorant Bottles for Personal Care

▶ Color: Pantone-matched or custom color ▶ Surface Processes: Spraying, electroplating, hot stamping, printing (silk screen/offset printing), etc.

- Material:PP/AS

- Capacity :15ml, 30ml, 50ml, 75ml,

- 15ml: Diameter : 36.8mm; Height : 111.8mm;

- 30ml: Diameter : 36.8mm; Height : 111.8mm;

- 50ml: Diameter : 36.8mm; Height : 111.8mm;

- 75ml: Diameter : 36.8mm; Height : 111.8mm;

Fully Customizable

New products can be customized and developed according to requirements.

- Raw Materials: Environmentally friendly materials, such as PETG/PP/ABS/PET/PMMA/AS.

- Product Development: The company has a professional R&D team, covering product drawing, mold making, mold testing, prototyping, and sample confirmation.

- Product Category: Cream Jars, Toner Bottles, Lotion Bottles, Aerosol-Free Bottles, Skincare Bottles, Makeup Powder Cases, Lipstick Tubes, Deodorant Bottles, and other plastic cosmetic containers

- Product Specifications: Customization is available for sizes ranging from 3ML to 500ML.

- For new product development (including mold making), samples for confirmation will be provided within 60 days; for existing product prototyping, samples for confirmation will be provided within 7 days.

- The first batch of orders will be delivered within 20 days after sample confirmation.

various production processes

Injection molding process for cosmetic plastic jars/bottles

High-precision injection molding process ensures uniform wall thickness.

Electroplating process for cosmetic plastic containers

Adopt advanced electroplating process

Printing process for cosmetic plastic containers

Our eco-friendly printing process meets EU cosmetic packaging standards

Eco-friendly product packaging for cosmetic containers

Both finished products and semi-finished products are packed separately with pegboards to prevent scratches and damage.

Spray coating process for cosmetic plastic bottles

Matte finish achieved via advanced spray coating process

Blow Molding Process

The product adopts advanced blow molding process to ensure uniform wall thickness of the bottle body.

our testing equipment

The entire process from development to production must undergo quality control by QC using testing equipment,

and we ensure quality and efficiency for each batch of orders.

Tensile tester testing for plastic cosmetic container lids

All products pass tensile tester testing before shipment

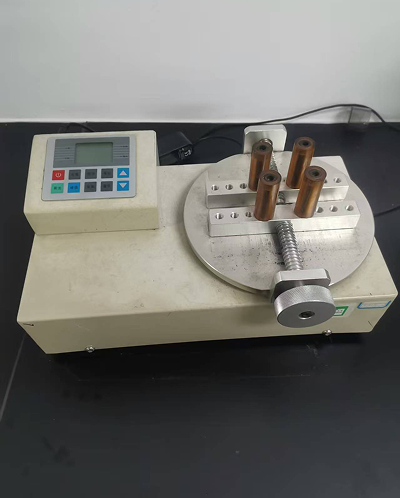

Torque tester testing for cosmetic bottle caps

Check the tightness between the bottle body

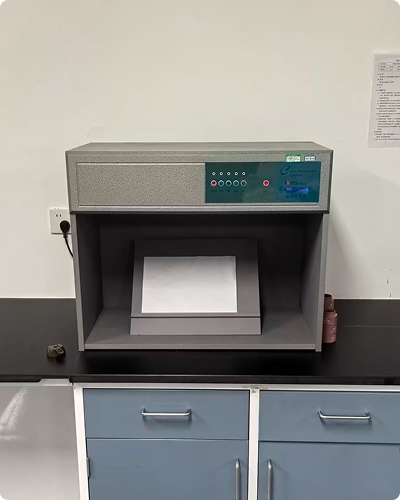

Steel building system

Check whether the product color, printing color, paint color, and other colors are consistent with the sample.

vacuum leak detector

The vacuum leak tester is used to verify the airtightness of lotion bottles and cream jars

High and Low Temperature Tester

The high and low temperature tester is used to evaluate the durability of plastic cosmetic containers under extreme temperature conditions (-60°C to +60°C).

Suyuan Packaging Technology

Suyuan Packaging Technology Co., Ltd. was founded in October 2010. It covers a total area of 23,000 square meters, with a workshop area of 15,000 square meters.

The company is located in Xiaoyue Town, Shangyu District, Shaoxing City. It is a professional enterprise specializing in the production of daily chemical packaging, including various cream jars, lotion bottles, vacuum bottles, cosmetic bottles (and caps), and acrylic bottles.

A Professional and Reliable Plastic Cosmetic Container Manufacturing Team。

I have 15years of experience in the industry, which allows me to quickly understand your needs and develop the most suitable procurement plan for you.

Our product's patent certificates and quality system certificates

We have rich project experience and can tailor a solution for your project based on your needs, providing excellent quality at a low cost.

Our clients will discuss business and select samples on-site.

Common Questions

Most Popular Questions.

All the issues listed here are those our customers encountered upon receiving goods or during filling, and we have resolved every single one of them. If you encounter similar problems, please do not worry—we will take care of solving them for you.

Lid seal failure, leading to cream oxidation or leakage.

During production, our on-site QC team conducts regular product dimension inspections every 2 hours and performs mating tests. We use high-quality PE gaskets inside the lids, which have a moderate hardness and softness to ensure a tight seal. The torque of the bottle/lid meets the standard of 30 N·m. When the bottle is filled with water, the lid is tightened, and the bottle is placed sideways for 24 hours, there is no liquid leakage.

The jar body/lid is prone to damage, which impairs the product's texture.

It mainly covers two aspects: 1. During production, we use brand-new raw materials instead of recycled materials to enhance the product’s toughness. 2. For issues that may occur during transportation, we use hole-punched foam boards for all products in packaging—each bottle or lid is fixed to prevent shaking. The outer cartons are high-quality and resistant to damage. The strapping tapes are tightened in an “I” or “well” shape, and each pallet is tightly wrapped with stretch film. This ensures no product damage during transportation.

The cream leaves severe residue, making it inconvenient to use and causing waste.

During the development phase, we designed a certain rounded angle on the inner side of the bottle bottom, which works with the use of a spatula. The inner wall of the bottle body has a high smoothness, preventing the cream from sticking to the wall and leaving no residue during use.

The jar lid offers a poor opening and closing experience, with issues like jamming, being too loose, or too tight.

The main cause is product deformation resulting from poor control of process parameters during production. We establish process parameter standards during the development and mold testing phase, strictly implement them during production, and have on-site QC conduct regular inspections. Every batch of products is traceable.

Printing or hot stamping peeling off, which harms the brand image.

- Protect the products well during production and conduct oil stain removal treatment. 2. Adjust the flame treatment properly during printing and hot stamping. 3. Use inks and hot stamping foils that are compatible with the bottle material.

Do you want to find the original manufacturing factory to earn more profits?

We own a factory with years of experience, offering free samples, guaranteeing product quality and delivery time, and solving any problems you encounter. Choosing us will maximize your benefits.

Get Samples Now !

Check out the samples of our packaging products. See the quality of our products for yourself, and let’s officially start our cooperation!